Piston Pump Repair

Trillium specializes in Piston pump service and has made unparalleled investments to provide the absolute highest levels of service and support for your Stokes, Kinney and Leybold based systems, as well as our own Univac 100, 200 and 400 pumping systems.

Rebuild and Testing Process

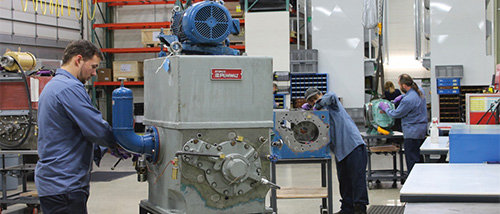

Trillium takes great care to ensure each Piston pump repair is performed to our internal specifications, as well as your requirements. Highlights of the process include:

- Detailed incoming inspection including photos taken from a number angles – these are used later in the process to ensure the product is returned to you in the same configuration, including any accessories installed on the pump

- Thorough disassembly, cleaning and inspection process to identify any parts no longer within specification that require replacement

- Industry leading block inspection and reboring process, which restores the concentricity and surface of this critical area of the pump

- Expert assembly by fully trained technicians done safely with ergonomically designed work stations and the appropriate material handling equipment

- Comprehensive testing to verify base pressure, pumping speed, motor current, pump temperature and a number of other key performance criteria. Copy of final test report provided.

Parts Manufacturing

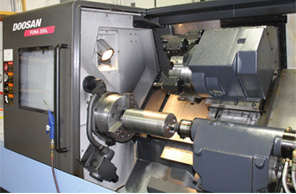

Our In-House parts manufacturing center features state-of-the-art CNC machining equipment and is fully equipped with SolidWorks and CAD/CAM, as well as a detailed quality control system.

As our Univac line is an exact drop-in replacement for the MicroVac line, every part down to the nuts and bolts are in stock and available to speed the rebuild of your pump. In addition we manufacture our own parts for many of the Kinney and Leybold Piston pumps.

Service Centers

Trillium repairs rotary piston pumps, including Stokes, Kinney and Leybold from 3 US service centers – no other 3rd party repair company offers this level of support.