Anyone who uses legacy LAM Etchers knows that their chillers are critical in ensuring high wafer yield for the fab. Sadly, the primary manufacturers for the chillers on these systems are no longer supporting this older technology. While we do our best to repair these old chillers, it is getting harder and harder to keep them going. Added to this, these old Freon based units are energy hogs compared to newer Peltier device technology which uses a “graduated, on demand” approach when drawing electricity. Older units consume about the same amount of electricity all the time, whether idle or actively removing heat from the Etcher. There couldn’t be a better time to upgrade these old chillers, with fab utilization and chamber uptime more important than ever. Contact us to discuss upgrading at insidesales@trilliumus.com

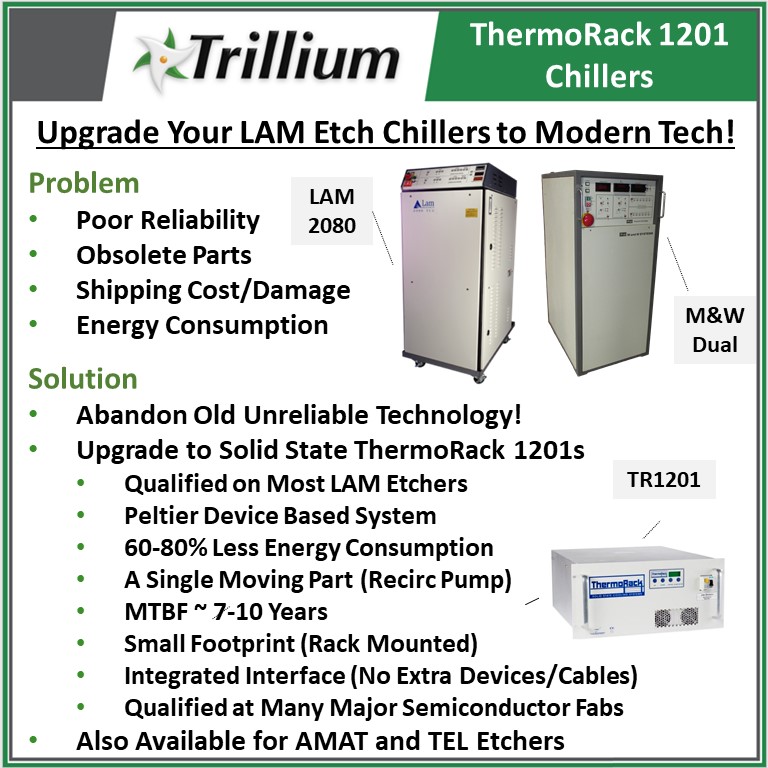

Problem:

- Poor reliability

- Obsolete parts

- Shipping cost/damage

- Energy consumption

Solution

- Abandon old unreliable technology

- Upgrade to Solid State ThermoRack 1201s

- Qualified on most LAM etchers

- Peltier device based system

- 60-80% less energy consumption

- A single moving part (recirc pump)

- MTBF, approx. 7-10 years

- Small footprint (rack mounted)

- Integrated interface (no extra devices/cables)

- Qualified at many major semiconductor fabs

- Also available for AMAT and TEL Etchers